Application Of Boron Nitride in The Release Of Metallic Materials

Mar 21, 2025

The application oon nitride (BN) in metal material release is mainly reflected in its excellent lubricity, high temperature resistance and chemical stability. The following are the specific applications of boron nitride in metal material release:

1. Lubricity

Boron nitride has a layered structure similar to graphite, and the interlayer force is weak, so it shows good lubricating properties. In the process of metal demolding, boron nitride can be used as a lubricant to reduce the friction between the mold and the metal material, thus reducing the demolding resistance and preventing the metal material from being damaged during demolding.

2. High temperature resistance

The melting point of boron nitride is as high as 3000°C, and it can still maintain stable physical and chemical properties at high temperatures. In high-temperature metal processing (such as casting, forging, etc.), boron nitride can effectively withstand high-temperature environments, avoiding lubrication failure or mold damage caused by high temperature.

3. Chemical Stability

Boron nitride is chemically inert to most metals and molten metals and does not easily react with metals. This makes it not contaminate the metal material during the metal release process, ensuring the purity and surface quality of the metal products.

4. Mold release agent

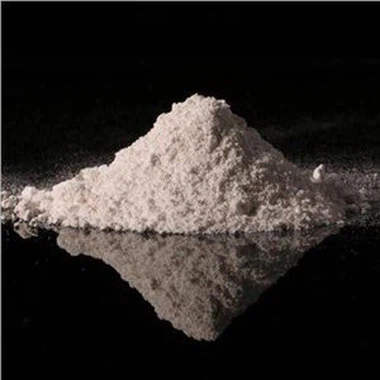

Boron nitride is often used as a mold release agent, especially in precision casting and high temperature molding process. It can be applied to the mold surface in the form of powder, spray or coating to form a layer of uniform lubricating film, which helps the metal material to be smoothly demolded, and at the same time, protects the mold surface and prolongs the life of the mold.

5. Application in composite materials

Boron nitride can also be composite with other materials (such as ceramics, graphite, etc.), made of high-performance mold release materials. This composite material not only has the lubricity and high temperature resistance of boron nitride, but also enhances the mechanical strength and wear resistance of the mold.

6. Application fields

Casting industry: used for mold release of light metals such as aluminum alloy and magnesium alloy.

High-temperature molding: such as titanium alloy, nickel-based alloys and other high-temperature alloy mold release.

Precision machining: in precision casting and injection molding, to ensure smooth mold release of metal parts with complex shapes.

With its excellent lubricity, high temperature resistance and chemical stability, boron nitride plays an important role in the mold release of metal materials, especially in the field of high temperature and precision machining. It not only improves the demolding efficiency, but also prolongs the service life of the mold, while ensuring the quality of metal products.

Shengyang New Material Co., Ltd. is committed to the production of boron nitride and boron nitride processed products, and can customize various boron nitride insulating ceramic parts according to customer needs. Contact us if necessary.

Tel:+8618560961205

Email:sales@zbsyxc.com