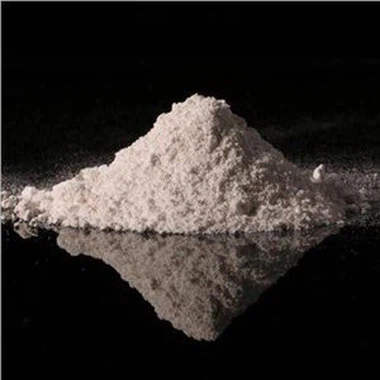

Boron Nitride Ceramic Parts Are Machined This Way

Aug 18, 2023

Boron nitride ceramics are highly sought after in the manufacturing industry due to their remarkable properties such as high resistance to wear, high thermal conductivity, and electrical insulation. The production process of boron nitride ceramics involves several key steps including mixing of raw materials, shaping, pressing, and sintering.

First, the raw materials are mixed in a ball mill to achieve a uniform and consistent blend. The mixture is then shaped through a process called isostatic pressing or extrusion to form the desired shape and size. The next step involves sintering the shaped parts in a high-temperature furnace to obtain the final product with the desired characteristics.

Boron nitride ceramics have a range of applications, including but not limited to high-temperature crucibles for melting or casting metals and alloys, and in the semiconductor industry for its electrical insulation properties. The material is also used in the production of cutting tools, wear-resistant parts, and as a coating for some reactor components and furnace linings, among other applications.

Overall, boron nitride ceramics is a valuable material in modern industries due to its exceptional properties. With continued research and advancement in technology, it is expected that the material will only find more applications in various sectors.