Advanced Applications Of Boron Nitride Coatings in Sealing Gaskets

May 13, 2025

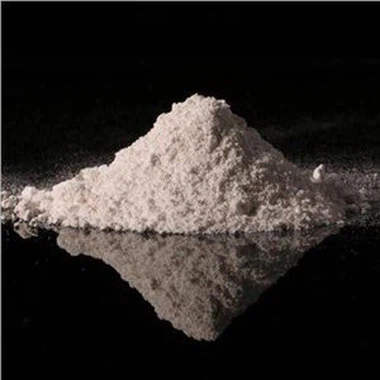

In a wide range of industrial equipment, sealing gaskets play a crucial role in preventing fluid leaks and isolating gases and liquids. As working environments become more extreme-featuring high temperatures, pressure, and corrosive media-traditional sealing materials are reaching their performance limits. Boron nitride (BN) coatings, as high-performance functional layers, are increasingly integrated into gasket designs to improve overall functionality.

Key advantages of BN coatings include:

Outstanding High-Temperature Resistance:

With a melting point of around 2973°C, BN coatings allow gaskets to perform reliably in high-temperature conditions without decomposition or deformation.

Self-Lubricating Properties:

BN's layered, graphite-like structure provides excellent dry lubrication, reducing friction during installation and improving sealing integrity.

Excellent Chemical Stability:

BN resists strong acids, alkalis, and various organic solvents, effectively protecting gaskets from chemical degradation.

Electrical Insulation and Thermal Conductivity:

These properties make BN-coated gaskets suitable for specialized applications in electronics and vacuum systems.

Typical applications include:

Sealing systems in refining and petrochemical equipment, dealing with hot steam and hydrocarbon mixtures.

Furnaces and heat treatment systems, where gaskets must endure extreme temperatures.

Vacuum packaging and semiconductor manufacturing, requiring precise, contamination-free sealing.

High-temperature sealing in electric vehicle battery systems and related thermal management components.

As demands for better sealing performance and longevity increase, boron nitride coatings demonstrate great potential in gasket technology. With ongoing advancements in BN coating processes, their application in high-end sealing solutions is expected to expand, ensuring safe and efficient operation across multiple industries.