Applications Of Boron Nitride Coatings in Metal Release Processes

May 14, 2025

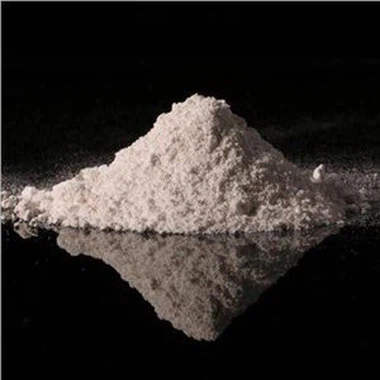

In metal manufacturing, mold release agents play a critical role in ensuring product quality, mold longevity, and operational efficiency. Traditional agents like graphite offer lubrication but suffer from drawbacks such as contamination and carbon buildup. In recent years, boron nitride (BN) coatings-particularly those based on hexagonal boron nitride (h-BN)-have gained attention for high-temperature metal release, especially in the processing of aluminum, magnesium, and zinc alloys.

(1). Key Properties of Boron Nitride Coatings

1. Outstanding High-Temperature Resistance

h-BN remains stable in air up to over 900°C and can withstand temperatures exceeding 1800°C in inert atmospheres, making it ideal for most metal thermal processing environments.

2. Excellent Non-Wettability

BN exhibits natural non-wettability with molten metals, especially aluminum, zinc, and magnesium. This prevents metal adhesion to molds and improves product integrity.

3. Chemical Inertness and Corrosion Resistance

BN does not react with metals, slags, or fluxes at high temperatures, effectively protecting mold surfaces and extending their service life.

4. Superior Lubrication and Insulation

As a ceramic, BN offers dry lubrication and excellent electrical insulation, suitable for complex or sensitive molding conditions.

(2). Application Scenarios in Metal Release

1. Aluminum Die Casting Molds

BN coatings are applied to mold cavities and ejector pins to prevent aluminum adhesion, extend mold life, and reduce cleaning frequency.

2. Metal Extrusion and Forging

Used on punches and mold surfaces to reduce friction and sticking between metal and tooling, improving shaping accuracy and tool performance.

3. Brazing and High-Temperature Sintering

BN is coated on graphite or metal molds to facilitate smooth part release and prevent surface contamination.

4. Investment Casting Shell Protection

When applied to ceramic or metal molds, BN forms a dense protective barrier that prevents molten metal infiltration and thermal shock damage.

(3).Advantages and Economic Benefits

Reduced mold cleaning and maintenance frequency, lowering labor costs

Improved surface finish and product yield, reducing rework

Extended mold lifespan, reducing tool replacement expenses

Environmentally friendly alternative to graphite, minimizing carbon pollution and smoke emissions

Boron nitride coatings, with their exceptional thermal stability and non-stick characteristics, offer significant advantages in metal mold release applications. As industries seek cleaner, more efficient, and longer-lasting solutions in metal forming, BN coatings are poised to play an increasingly vital role in process optimization and technology advancement.

Shengyang New Material Co., Ltd. is committed to the production of boron nitride and boron nitride processed products, and can customize various boron nitride insulating ceramic parts according to customer needs. Contact us if necessary.

Tel:+8618560961205

Email:sales@zbsyxc.com