Applications Of Boron Nitride in Anti-Corrosion

Feb 18, 2025

Boron Nitride (BN) has significant potential in anti-corrosion applications due to its excellent chemical inertness, high-temperature resistance, and corrosion resistance. Below are the main applications and advantages of boron nitride in anti-corrosion:

High-Temperature Anti-Corrosion Coatings:

Boron nitride can be used to prepare high-temperature anti-corrosion coatings, protecting metals or other materials from oxidation, corrosion, and chemical erosion in high-temperature environments.

Application Fields:

Aerospace engine components

High-temperature furnace linings

Chemical reactor interiors

Corrosion-Resistant Composite Materials:

Adding boron nitride as an additive to ceramic, metal, or polymer matrices can enhance the corrosion resistance of composite materials.

Application Fields:

Chemical equipment (e.g., pipelines, valves, pumps)

Marine engineering (e.g., desalination equipment, ship components)

Nuclear industry (e.g., reactor components)

Electrochemical Anti-Corrosion:

The high insulation and chemical stability of boron nitride make it an ideal material for electrochemical anti-corrosion applications, such as electrode coatings or isolation layers.

Application Fields:

Anti-corrosion coatings for batteries and supercapacitors

Protective layers for electrochemical sensors

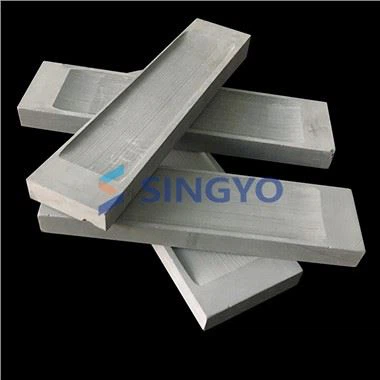

Sealing Materials in Corrosive Environments:

Boron nitride can be used to manufacture corrosion-resistant seals and gaskets, suitable for strong acids, alkalis, or other corrosive environments.

Application Fields:

Sealing in chemical equipment

Corrosion-resistant components in semiconductor manufacturing

Anti-Corrosion Coating Additives:

Adding boron nitride powder to anti-corrosion coatings can enhance the chemical resistance and wear resistance of the coating.

Application Fields:

Metal structure protection (e.g., bridges, ships, storage tanks)

Surface protection for industrial equipment

Advantages of Boron Nitride in Anti-Corrosion

Chemical Inertness:

Boron nitride exhibits high stability against most acids, alkalis, and solvents, effectively resisting chemical corrosion.

High-Temperature Resistance:

It remains stable at high temperatures (up to 2000°C), making it suitable for high-temperature corrosive environments.

Low Surface Energy and Non-Wettability:

The surface of boron nitride is not easily wetted by molten metals or corrosive liquids, reducing contact between the material and corrosive media.

High Insulation:

In electrochemical corrosion environments, the high insulation of boron nitride can block current, preventing electrochemical corrosion.

Mechanical Properties:

Boron nitride has high hardness and wear resistance, enabling it to withstand both mechanical wear and corrosion.

Specific Application Cases

Aerospace Industry:

Boron nitride coatings are used to protect turbine engine blades from high-temperature oxidation and thermal corrosion.

Chemical Industry:

Boron nitride composites are used to manufacture corrosion-resistant reaction vessels, pipelines, and valves.

Marine Engineering:

Boron nitride coatings are used to protect metal components in desalination equipment from seawater corrosion.

Nuclear Industry:

Boron nitride is used in radiation-resistant and corrosion-resistant components in nuclear reactors.

Electronics Industry:

Boron nitride serves as an insulating and anti-corrosion material to protect electronic components from chemical corrosion.

Comparison of Boron Nitride with Other Anti-Corrosion Materials

| Property | Boron Nitride (BN) | Polytetrafluoroethylene (PTFE) | Ceramic Coatings | Stainless Steel |

|---|---|---|---|---|

| Chemical Resistance | Extremely High | High | High | Moderate |

| High-Temperature Resistance | Extremely High (2000°C) | Low (260°C) | High (1500°C) | Moderate (800°C) |

| Mechanical Strength | High | Low | High | High |

| Insulation | High | High | High | Low |

| Cost | High | Low | Moderate | Moderate |

Shengyang New Material Co., Ltd. is committed to the production of boron nitride and boron nitride processed products, and can customize various boron nitride insulating ceramic parts according to customer needs. Contact us if necessary.

Tel:+8618560961205

Email:sales@zbsyxc.com

WhatsApp:+8613964302243