Boron Nitride Also Plays A Large Role in The Automotive Manufacturing Industry

Apr 09, 2025

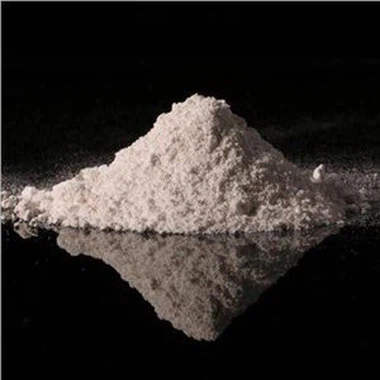

Boron nitride (BN) is mainly used in the following fields in the automotive industry due to its excellent high temperature resistance, wear resistance, lubrication, insulation and chemical stability, etc. Combined with its performance advantages and the demand characteristics of the automotive industry, the specific analyses are as follows:

1. Engine System: High Temperature Resistant and Friction Reducing Lubrication

(1) Piston Rings and Cylinder Coating: Boron nitride can be used as a high temperature lubrication coating material, sprayed on the piston rings, cylinder walls or bearing surfaces to reduce the coefficient of friction (friction coefficient as low as 0.1-0.2), and improve engine efficiency. Boron nitride can be sprayed on piston rings, cylinder walls or bearing surfaces as a high-temperature lubrication coating material to reduce the coefficient of friction (coefficient of friction as low as 0.1-0.2), minimize wear and improve engine efficiency. Especially in high temperature working conditions (such as turbocharged engines), its high temperature resistance (antioxidant temperature can reach 900℃ or more) can avoid the failure of traditional lubricants and prolong the life of parts.

(2) Valve tappet and camshaft lubrication: as a solid lubricant added to the grease, or directly prepared into self-lubricating composite materials, used in high-load contact parts, reducing dry friction and wear during start-stop, and reducing noise.

2. Gearboxes and transmission systems: efficient lubrication and wear-resistant

(1) Gearbox lubrication: adding boron nitride nanoparticles to the gear oil of manual or automatic gearboxes can enhance the strength of lubrication film and reduce tooth wear, which is especially suitable for high-temperature and high-load conditions (such as dual-clutch gearboxes).

(2) Clutch Friction Plate: As an additive of friction material, it enhances the high temperature resistance and friction stability of the friction plate, avoiding clutch failure caused by overheating, and at the same time, reducing the emission of wear dust.

3. Electrical and Electronic Systems: Insulation and Heat Dissipation

(1) High-voltage Insulation Materials: In the high-voltage battery packs and motor controllers of electric vehicles (EVs), boron nitride is used to prepare insulating coatings or composites (e.g., boron nitride - epoxy resin), which provide high dielectric strength (>30kV/mm) and high-temperature-resistant insulating protections to ensure electrical safety.

(2) Thermally conductive interface materials: as a thermally conductive filler (e.g., boron nitride ceramic particles) added to the heat dissipation silica gel or gaskets, to enhance the thermal efficiency of the battery module, power electronic components, to avoid localized overheating (thermal conductivity of up to 300-400 W/(m-K)).

4. Lightweight and structural materials: reinforced composites

(1) Lightweight and high-strength parts: composite boron nitride nanosheets or fibers with metals (such as aluminum, magnesium alloy) or polymer materials (such as nylon, carbon fiber composites) to prepare lightweight structural parts (such as body mounts, chassis parts), improve material strength and corrosion resistance, while reducing the weight of the entire vehicle (weight reduction of 10%-20%), improve fuel economy or electric vehicle range.

(2) Enhancement of high-temperature components: Used in exhaust system components (e.g. turbocharger housing, exhaust pipe heat insulation) to enhance the high-temperature and oxidation resistance of the material to adapt to the stringent emission requirements under the National VI/National VII standards.

5. Braking system: high-temperature-resistant friction and noise reduction

(1) Coating for brake pads and discs: Adding boron nitride to brake pad formulations can regulate the coefficient of friction, reduce brake fade at high temperatures (temperature resistance up to 600°C or more), and at the same time, reduce braking noise and dust pollution.

(2) Brake caliper seals: As a filler for sealing materials, it improves the high temperature resistance and aging resistance of rubber seals, prevents brake fluid leakage, and safeguards the reliability of the braking system.

6. Other Functional Applications

(1) Catalytic Converter Carrier Coating: Utilizing the chemical inertness and high specific surface area of boron nitride, it is used as a catalyst carrier or coating material to enhance the efficiency of exhaust gas treatment and reduce the dosage of precious metals (e.g. platinum and palladium).

(2) Fuel/lubricant additives: Nano-sized boron nitride particles are used as anti-wear agents and added to fuel or oil to reduce the wear and tear of injector nozzles, piston rings, and other components, and to enhance engine cleanliness and longevity.