How Is Boron Nitride Made Into High-Performance Drill

Oct 07, 2023

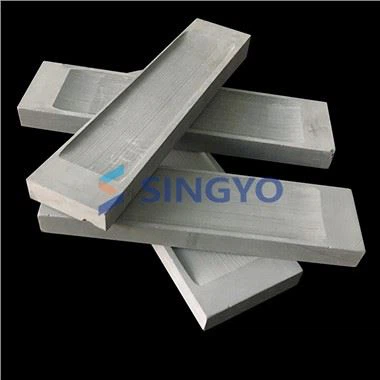

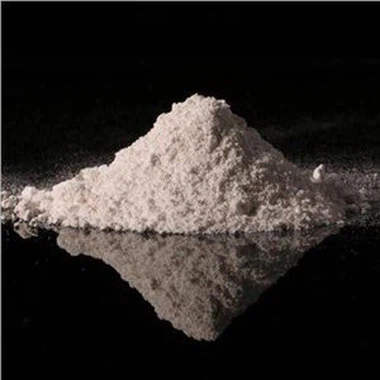

Boron nitride, also known as BN, is a synthetic material that has excellent thermal and chemical stability. It is commonly used in the petroleum industry to make high-performance drill bits for oil drilling operations. The process of making BN drill bits involves several steps, including mixing boron oxide and nitrogen gas in a furnace, and then subjecting the resulting material to high temperatures and pressures to produce a solid block of BN.

In the petroleum industry, BN drill bits have several advantages over traditional drill bits made of steel. They are more durable and can withstand high temperatures and pressures, making them ideal for use in high-temperature drilling environments. They are also more resistant to wear and corrosion, which helps to reduce drilling downtime and improve productivity.

BN drill bits are widely used in the oil and gas industry for drilling through hard rock formations, such as shale and sandstone, as well as for drilling in deep water environments. They are also used in other industries, such as aerospace and automotive, where high-performance drilling is required.

In conclusion, the development and use of BN drill bits in the petroleum industry has revolutionized the way oil and gas wells are drilled. With their superior performance and durability, they have helped to reduce costs and increase productivity, while also improving safety and environmental sustainability. As such, BN drill bits are a key driver of innovation and progress in the petroleum industry and beyond.

Shengyang New Material Co., Ltd. is committed to the production of boron nitride and boron nitride processed products, and can customize various boron nitride insulating ceramic parts according to customer needs. Contact us if necessary.

Tel:+8618560961205

Email:sales@zbsyxc.com

WhatsApp:+8613964302243