The Key Role Of Boron Nitride in LED Technology: A Material Choice For Enhanced Thermal Management And Efficiency

Jul 18, 2025

1. Challenges in LED Thermal Management

While LEDs are energy-efficient and highly reliable, they still generate a significant amount of heat during operation. If this heat is not effectively dissipated, the junction temperature rises, leading to decreased luminous efficiency, color shift, device aging, and potential failure. As a result, efficient thermal management materials are essential in modern LED design.

2. Overview of Boron Nitride Properties

Boron nitride, especially hexagonal boron nitride (h-BN), is a ceramic material known for its exceptional physical and thermal properties. Its key advantages include:

High thermal conductivity: Up to 200 W/m·K, ideal for heat dissipation;

Excellent electrical insulation: High dielectric strength for safe operation under voltage;

Chemical and thermal stability: Resistant to oxidation and high temperatures;

Low dielectric constant: Suitable for high-frequency and high-speed electronics;

Versatile processing: Available in powder, coating, ceramic, and film forms.

3. Main Applications of Boron Nitride in LEDs

1. Thermally Conductive Fillers

Boron nitride is widely used as a thermal filler in LED packaging materials like silicone and epoxy resins. Compared to traditional fillers such as alumina or aluminum nitride, BN achieves better thermal performance at lower loading ratios, preserving the mechanical flexibility of the material.

2. Thermal Interface Materials (TIMs)

BN-filled thermal pastes and pads serve as interface materials between the LED chip and heat sink. These materials help reduce thermal resistance and enhance heat transfer efficiency, making them essential in high-power LED systems.

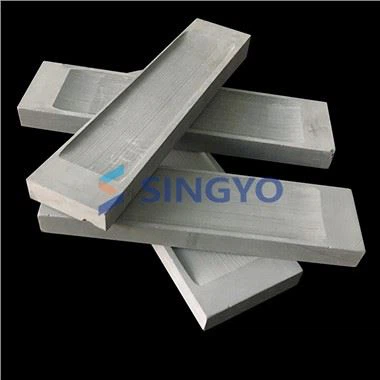

3. Boron Nitride Ceramic Substrates

BN ceramics, due to their high thermal conductivity and electrical insulation, are excellent substrate materials for compact and high-power LED modules. Their dimensional and thermal stability makes them suitable for long-term operation under harsh conditions.

4. BN Coatings and Thin Films

Boron nitride coatings and films can be applied to LED housings, reflectors, or protective layers, offering not only thermal benefits but also moisture resistance, chemical protection, and improved optical performance.

4. Impact of Boron Nitride on LED Performance

Integrating BN into LED designs can significantly enhance overall performance:

Reduced junction temperatures, extending LED lifespan;

Improved luminous efficiency, minimizing light decay due to heat;

Increased stability and reliability, resisting thermal shock and degradation;

Enables miniaturization and high-density packaging for modern LED applications.

5. Future Trends and Prospects

As LED technology advances toward higher power, smaller form factors, and longer lifespans, the demand for advanced thermal management materials will grow. The multi-functional nature and engineerability of BN make it well-positioned for future applications. Emerging developments in BN nanosheets, composite materials, and coating technologies are expected to further enhance the performance and efficiency of next-generation LEDs.

Boron nitride is becoming an indispensable material in LED packaging and thermal systems due to its unique combination of high thermal conductivity and electrical insulation. Its role in improving heat dissipation, efficiency, and reliability lays a solid foundation for the continued evolution and innovation of LED technology.

Shengyang New Material Co., Ltd. is committed to the production of boron nitride and boron nitride processed products, and can customize various boron nitride insulating ceramic parts according to customer needs. Contact us if necessary.

Tel:+8618560961205

Email:sales@zbsyxc.com