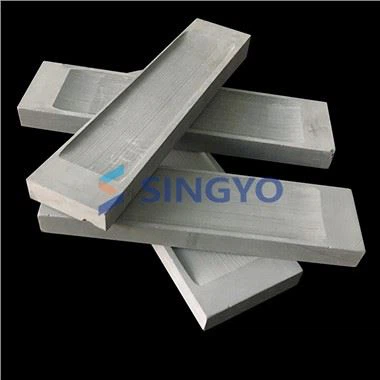

Conductive Ceramic Evaporation Boat

Our company is committed to the research and production of conductive ceramic evaporation boat.

Description

The composite ceramic evaporation boat is a general term for all evaporation vessels and is suitable for use as a fuser for molten metal such as molten aluminum or zinc sulfide in vacuum evaporation technology.

The evaporation boat is mainly evaporating aluminum, copper and silver, and widely used in a wide range of applications, such as vacuum evaporation packaging materials, capacitor metallization coating, display plating, hot stamping, anti-counterfeit marking, reflective coating and paper, textile aluminum plating and other industries.

Our evaporation boat to take the optimized three-component synthesis structure, enhance the evaporation boat thermal shock resistance and bending strength resistance, alleviate the difference due to the different thermal expansion coefficient of various materials, avoid the evaporation boat working at high temperature, due to their own release of heat and lead to fracture; It enhances the wettability of the evaporation boat to the metal, so that the aluminum solution is easy to diffuse to the surface of the whole tank, and improves the evaporation efficiency. The corrosion resistance of the evaporating boat is enhanced, and the working life of the evaporating boat is prolonged.

Technology standard

Resistivity (normal temperature) | 300-2000μΩ·cm |

Evaporation velocity (1450℃) | 0.3-0.5g/min·cm2 |

Operating temperature | ≤ 1750℃ |

Heat conductivity (normal temperature 1450℃ ) | > 100/40W/mk |

Coefficient of thermal expansion(1450℃) | (4-6)×10-6K |

Bending strength (normal temperature) | > 150mpa |

Packing | Vacuum package |

Advantages

● A shorter pre-heating time>

● The molten aluminum is easier to spreading wetting

● Less spitting and bending of the boat's problems

● Longer working life

● Cost-efficient choice

Main Specifications

Specifications | L | B | H | Groove | L1 | B1 | H1 |

105x20x10 | 105 | 20 | 10 | C | 80 | 15 | 1.5 |

105×30×10 | 105 | 30 | 10 | 80 | 25 | 1.5 | |

110x7x5 | 110 | 7 | 5 | 80 | 4 | 2.5 | |

110×16×9 | 110 | 16 | 9 | 80 | 11 | 1.5 | |

110×20×10 | 110 | 20 | 10 | 80 | 15 | 1.5 | |

110x24x10 | 110 | 24 | 10 | 80 | 19 | 1.5 | |

110x26x10 | 110 | 26 | 10 | 80 | 21 | 1.5 | |

120x24x10 | 120 | 24 | 10 | 92 | 19 | 1.5 | |

120×30×10 | 120 | 30 | 10 | 92 | 25 | 1.5 | |

120x35x10 | 120 | 35 | 10 | 92 | 30 | 1.5 | |

125×30×10 | 125 | 30 | 10 | 92 | 25 | 1.5 | |

125x35x10 | 125 | 35 | 10 | 101 | 30 | 1.5 | |

130×24×10 | 130 | 24 | 10 | 101 | 19 | 1.5 | |

130x30x10 | 130 | 30 | 10 | 101 | 25 | 1.5 | |

130×35×10 | 130 | 35 | 10 | 101 | 30 | 1.5 | |

130×40×10 | 130 | 40 | 10 | 101 | 35 | 1.5 | |

140×30×10 | 140 | 30 | 10 | 112 | 25 | 1.5 | |

150x30x10 | 150 | 30 | 10 | 120 | 25 | 1.5 |

About delivery time

We will try our best to get the goods ready within 5 working days. If the order amount is large, we will estimate the time of getting the goods ready and inform the customer.

About inquiry mail

In order to improve efficiency and save your time, please specify the required size, resistivity and other data in the first email of inquiry, and we will give you a quotation as soon as we receive the email.